Our steel beam bridges are engineered to withstand heavy traffic and harsh environmental conditions, ensuring long-lasting performance with minimal upkeep. Available in various sizes and customizable designs, these bridges can be tailored to meet specific project requirements, including roadways, pedestrian paths, and industrial applications.

ZHUOPIN Steel Beam Bridge is the main load-bearing structure using steel bridge. Based on the main stress components, steel-frame bridges can be divided into steel arch bridges, cable-stayed bridges, and suspension bridges.

PARAMETER | |

Brand | ZHUOPIN |

Standard | GB Standard |

Certificates | ISO9001 |

Material Grade | Q235 / Q355 |

Type | Heavy Steel Structure |

Coating Treatment | Painted & Hot dip galvanized |

ZHUOPIN Steel Beam Bridge is the main load-bearing structure using steel bridge. Based on the main stress components, steel-frame bridges can be divided into steel arch bridges, cable-stayed bridges, and suspension bridges.

Steel Structure Bridge is a form of bridge, which means that the main load-bearing part of the upper structure of a bridge is made of steel. Like bridges, steel structure bridges are air roads that span rivers, lakes, and ocean obstacles. Most of the long-span bridges are prestressed steel-concrete bridges and steel structure bridges.

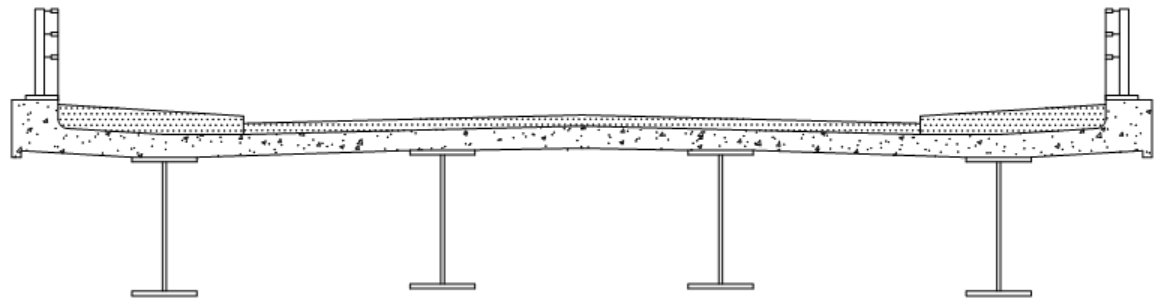

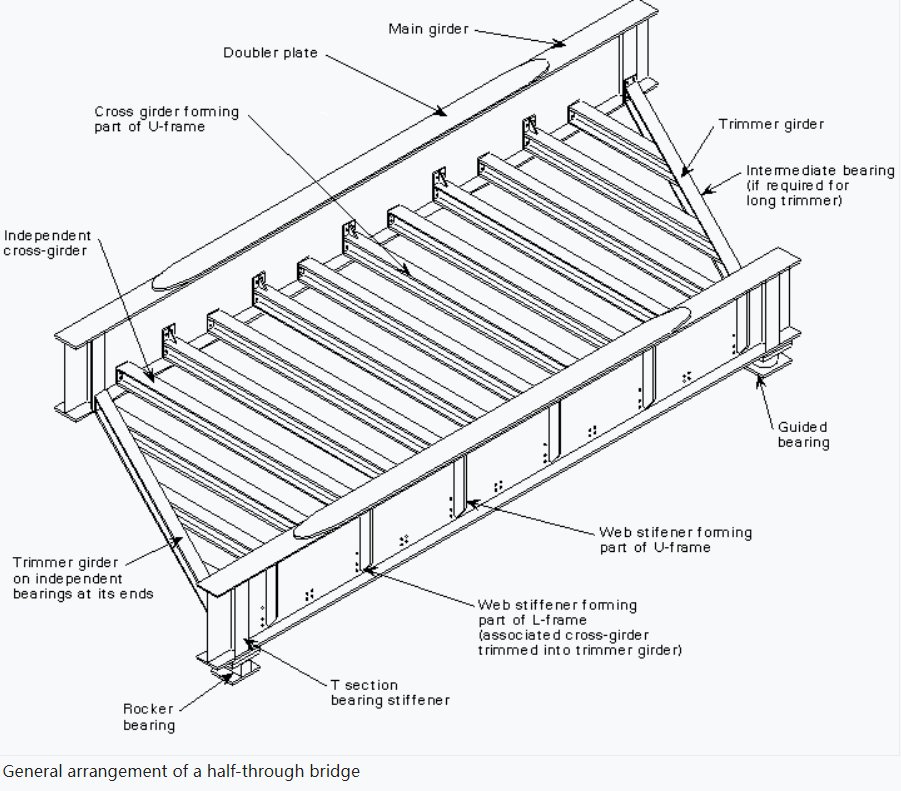

The structure of the steel structure bridge consists of the main bridge along its longitudinal direction. The span between the piers is called the span, the section of the main bridge spanning the main navigation hole is called the main span, and the span is the side span. The main materials used for steel structure bridges are steel plate, section steel, and high strength. The steel plate is mostly made of low-alloy steel, and the parts are made of cast steel and high-quality carbon. The main types of steel beams are ribbed beams, box beams, truss beams, and composite beams.

Beam bridges

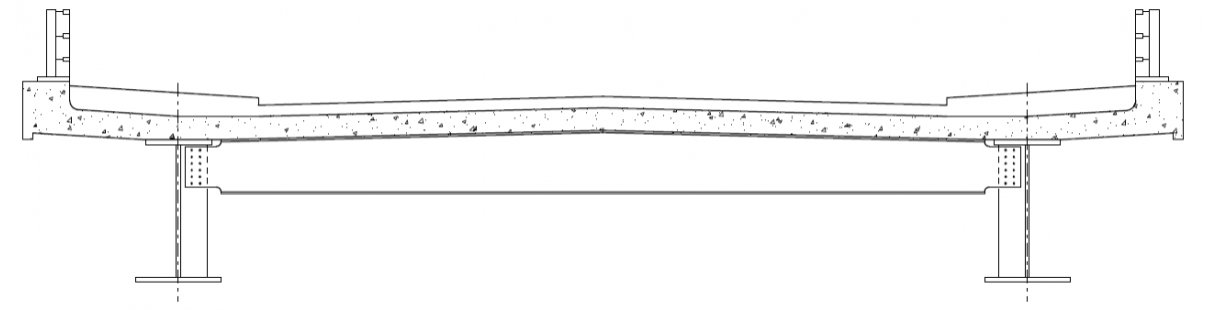

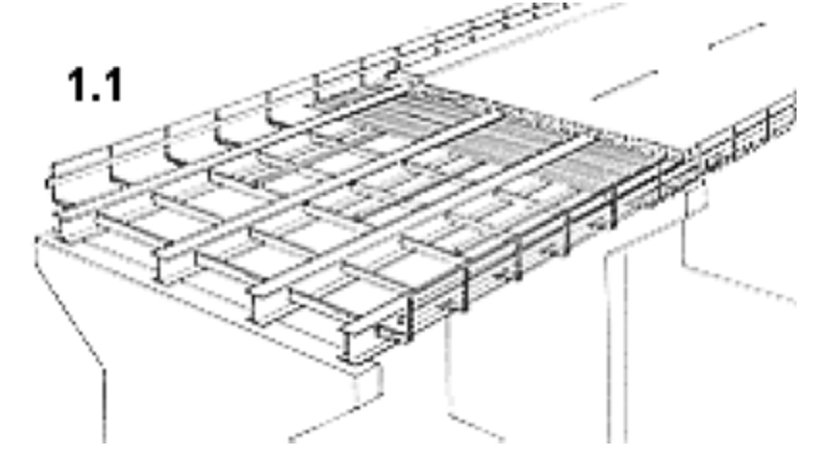

A beam and slab, or composite bridge is one where a reinforced concrete deck slab sits on top of steel I-beams, and acts compositely with them in bending. There are two principal forms of this beam and slab construction; multi-girder construction and ladder deck construction. Between them, they account for the majority of medium span highway bridges currently being built in the UK, and are suitable for spans ranging from 13m up to 100m. The choice between the two forms depends on economic considerations and site-specific factors such as form of intermediate supports and access for construction.

Advantages of steel structure bridges

1. The construction period is extremely short, and the actual construction period can be completed within a few days. Because all structural components are prefabricated in the factory, they can be pulled to the site for hoisting.

2. Easy to disassemble. If it needs to be removed later, the bolts can be removed directly, and all the steel can be reused for other buildings.

3. The appearance is light and beautiful.

4. Post-processing is convenient. For example, you need to add components to it and weld them on.

Which bridge is right for you?

Bridge Advice

When designing the construction of a new bridge, there are many considerations to be taken into place, but ultimately the span of the area to be bridged is important to ensure the right materials are chosen for the construction.

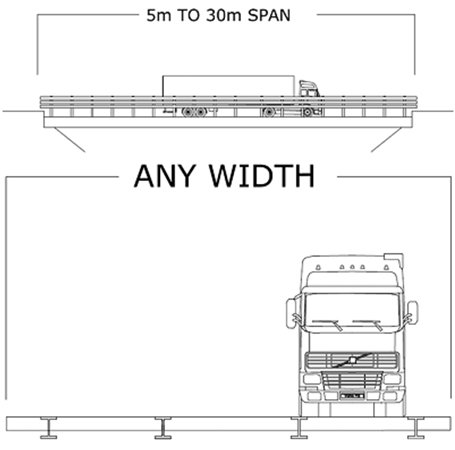

Steel Beam Bridge

Cross sections

-Beam - Structurally, the simplest type of bridge

-Relatively short span - 5m to 30m, although become more expensive after about 15m

-Can be any width, and are easily widened by simply adding more beams and deck

-Frequently used in pedestrian bridges and for highway overpasses and flyovers

-Footpaths can be built on both sides

-Can be built one or two beams at a time, often by direct craneage or by cantilever launch

-Longer spans require supporting pillars, making them unsuitable if lots of space is required beneath