-Long span (50m - 150m)

-Very strong, but also flexible

-Economical as allow a slender and lighter structure which is still able to span large distances

-Light weight is an advantage in earthquake-prone areas

-Modern and simple design makes attractive and distinct landmarks

-Easy to build in segments where in-situ construction or cantilever launch on rollers is not possible. This requires substantial piers and large counterweights

-Less suitable for very windy places due to its lightness

PARAMETER | |

Brand | ZHUOPIN |

Standard | GB Standard |

Certificates | ISO9001 |

Material Grade | Q235 / Q355 |

Type | Heavy Steel Structure |

Coating Treatment | Painted & Hot dip galvanized |

ZHUOPIN Through Truss Bridge

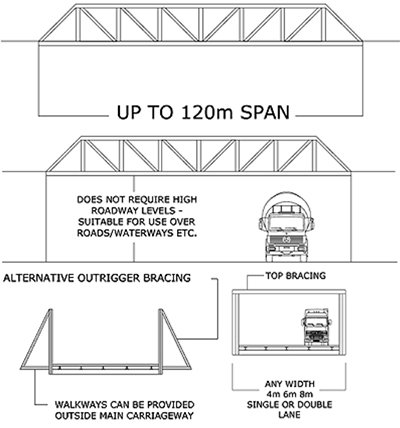

Truss bridges

A truss is a triangulated framework of individual elements or members which act primarily in tension or compression. Trusses have been used in a similar way to beams in composite decks (Oresund Approach Spans), as arches (Sydney Harbour Bridge), as cantilevers (Forth Rail Bridge) or as stiffening girders to suspension bridges (Forth Road Bridge).

Today, the truss girder form of construction usually proves expensive to fabricate because of the large amount of labour-intensive work in building up the members and making the connections, so they are seldom used for ordinary highway bridges. However, for through or half-through forms, truss bridges do offer a very stiff, lightweight solutions with minimum structural depth. Hence, they are widely used in the UK for footbridges, demountable bridges (Bailey bridges), gantries and longer span railway bridges (over 50m).

Advantages of steel structure bridges

1. The construction period is extremely short, and the actual construction period can be completed within a few days. Because all structural components are prefabricated in the factory, they can be pulled to the site for hoisting.

2. Easy to disassemble. If it needs to be removed later, the bolts can be removed directly, and all the steel can be reused for other buildings.

3. The appearance is light and beautiful.

4. Post-processing is convenient. For example, you need to add components to it and weld them on.

Which bridge is right for you?

Bridge Advice

When designing the construction of a new bridge, there are many considerations to be taken into place, but ultimately the span of the area to be bridged is important to ensure the right materials are chosen for the construction.